Study tours in Kitakyushu

Kitakyushu-city is the World leading Environmental Future city, and blessed with spectacular

and stunning nature. The city is the Industrial Innovation city greatly contributed to Japan’s

Industrial modernization since Japan’s modern Steel Industry operation commenced in Hitashida

in 1901.

Now Kitakyushu-city offers the various kind of Study tour such as Environment, Solid Waste

management, Industry, Science, Geography, Architecture, Economy as well as SDGs.

Our Study tour is offered as a package tour exclusively for your group.

Included items

・Making the Study tour planning

・Arrangement of visiting places

・Tour guide and interpreter

・Transportation such as Chartered vehicle

・Accommodations

・Meals ( Japanese cuisines and local delicacies )

Where to learn

We are offering various type of study tour utilizing the following learning resources, environment

and historical aspects. Feature of our study tour is the tailor-made in accordance with customer

requirement of learning.

Solid Waste management & Recycling

Kitakyushu-city is the advanced city of Solid waste management in Japan.

Comprehensive solid waste management system can be learned from waste collecting procedure

at household to the final stage of waste treatment such as incineration, landfill and recycling.

The city is promoting the low carbon society in Asia while taking leadership as the Environmental

Future City. The new generation technologies and the activities cooperated with Citizen to achieve

low carbon society can be learned.

|

|

Industrial modernization & KAIZEN strategy

Japanese industry at the end of 19th century was 200 years behind. Since Japan’s modern

Steel Industry operation commenced in 1901 in Kitakyushu, Japan became the world’s leading

industrialized country in only 100 years. There is the KAIZEN strategy in the background to

Japan becoming an industrialized country at a rapid speed.

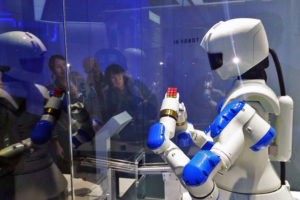

There are a lot of Museums and facilities where Science, Technology, Engineering and

Mathematics can be learned.

|

|

|

UNESCO World Heritage of Japan’s Meiji Industrial Revolution

The four sites of Yawata Steel Works in Kitakyushu area have been inscribed as Iron and

Steel Industry. The buildings of The Imperial Steel Works, Japan at Yawata Works of

Nippon Steel are the surviving components of Asia’s first successful integrated iron and

steel works.

|

|

|

There are a lot of unique construction designed by renowned architects and civil engineers,

that were constructed beginning of Japan’s Industrial modernization. The design philosophy

of designers focused on the future can be learned.

|

|

|

Geography is a field of science devoted to the study of the lands, features, inhabitants, and

phenomena of Earth. Kitakyushu has unique geographical features, therefore Earth and its

human and natural complexities and also how they have changed and come to be can be learned.

|

|

|

Related sites to the Study tour

Study tour to Kyushu Study tour in Nagasaki History of Industrial modernization